Current Location > Home > COOPERATION > Industry engineering

Current Location > Home > COOPERATION > Industry engineeringIndustry engineering

BEIJINGJIANYANTreatment Engineering Biomass Energy Project Reclaimed Water Project Sewage Engineering Industrial Wastewater

Engineering Aquaculture Wastewater

Treatment Engineering

Dairy Wastewater Treatment Engineering

At present, both overseas and domestic dairy products, such as yogurt, fresh milk, pure milk and milk powder, have be accessible to the common families, and become a kind of indispensable nourishment.

Dairy wastewater is mainly discharged during production of dairies, such as liquid milk, pasteurized milk, milk powder, ice cream and ice cream, yogurt, condensed milk, cheese, butter, dairy, cool and refreshing beverage.

The dairy plants can generate various wastewaters, such as all kinds of equipment wash water, ground flush water, butter-washing & mixing wastewater, as well as wastewater from dairy production. If such wastewater is directly discharged into water body, the adverse consequences may be caused, such as "black and odorous", and "eutrophication". Total nitrogen of dairy wastewater is about 60-100 mg/L at average, which mainly comes from protein in wastewater (protein content accounts for 2.7-2.8% in milk, while nitrogen accounts for about 16% of protein). When wastewater is just discharged from the shop, the protein has not been decompounded yet, ammonia-nitrogen concentration in wastewater is shown very low (and even lower than the national emission standard), therefore, the denitrogenation measures are often ignored during treatment of such wastewater, so that ammonia nitrogen in wastewater treated in such sewage stations are often beyond the standard. In fact, when protein (total nitrogen or Kjeldahl nitrogen in wastewater) is biodegraded in the biochemical unit, it can be degraded into forms of polypeptide protein, dipeptide and amino acid during ammoniation reaction; so that ammonia nitrogen is released into wastewater which makes ammonia nitrogen concentration increase. Thus, it is very necessary for dairy wastewater to remove nitrogen and phosphorus.

In view of some characteristics of dense dairy wastewater, such as high oil concentration, easy to biochemical degradation, Jianyan has developed some processes specific to different products.

Dairy Wastewater

The 1st generation of treatment process

Air flotation + aerobic treatment process

The conventional air flotation is mainly suitable for wastewater with more colloidal substances, which can be removed by this method. The treated wastewater is relatively clear through this process, but only organic matter, such as colloid in the wastewater can be removed, while the soluble organic matter can’t be removed; the effluent contains high COD, the running is not stable, so it can't meet the compliance discharge. Meanwhile, the air floatation can produce more sludge, which is difficult to treat due to very high moisture content in it; in addition, its operation cost is much high, therefore it is not used for wastewater treatment alone.

The 2nd generation of treatment process

Hydrolytic acidification + aerobic treatment process

The aerobic processes, such as biological contact oxidation and activated sludge method, can achieve good effect during dairy wastewater treatment with removal rate of COD up to 90%, the operation is relatively stable, however it needs blast aeration, so it means much power consumption and high operation cost. Moreover, it needs a long time to restart after shutdown maintenance "(usually a month or so)Annotation:Is not that repair takes a month? Rather than the maintenance required after a month or so and then start?".

The 3rd generation of treatment process

Anaerobic + aerobic treatment process

This process is featured as more investment, low operation cost, stable running, good treatment effect, and easy operation management. However, the pretreatment is poor, and anaerobic treatment process is not so stable.

At present the latest treatment process:

Hydrolysis acidification + oil separation + air floatation and oil removal + oil residue treatment + anaerobic + aerobic process

This process is featured as low operation cost, stable and reliable operation, no scum to be transported and less sludge production; in addition, it can produce biogas energy. Up to now, Jianyan has completed dozens of projects for dairy factory in whole country.

Biomass Energy (cow dung treatment) Project

Biomass energy project mainly utilizes faces from livestock & poultry farms; organic wastes from all kinds of processing plants, such as wineries and food factories; kitchen waste; agricultural wastes, such as straw, vegetable leaves, grass, and leaves; to pre-treat and conduct anaerobic fermentation, so as to produce methane gas to generate heat and power together. Key equipment introduced from Germany is featured as advanced and mature technology, simple and convenient operation, stable running, and high degree of automation and intensification. The electrical energy can be sold through connecting the power grid, and waste heat can be utilized for industrial and civil purposes, as well as greenhouse planting. Methane is also available as industrial and urban gas; the biomass liquid can be used as a liquid organic fertilizer; while biomass residues can be processed into solid organic fertilizer, which can directly provide fertilizer for crops or sales.

Process Characteristics

It combines the advantages of batch and continuous fermentation, realizes high concentration fermentation (solid content can reach over 18%), zero wastewater discharge and low energy consumption.

It employs medium- and high-temperature fermentation for high gas generation rate and short fermentation time

The system can fully utilize the generated power; employ fermentation tube for the external heating, so as to realize low-energy input and high-energy output, which is applicable to North China.

With advanced and reliable data collection and precision control system, it can accurately control temperature, pH, pressure and liquid flow; measure and monitor methane productivity and gas composition on line, so as to ensure the stable and effective operation of equipment.

It is featured as less infrastructure investment and small space required.

Reclaimed Water Project

It applies to treat bath water and wash water for recycling in the hotels, buildings, communities, schools, factories and mining enterprises.

一、 Reclaimed Water Treatment:

Reclaimed water is defined in term of water supply and drainage; such supporting facility for buildings and community is also called as reclaimed water facility.

The treated water can be used in flushing toilet, landscaping, car washing, road spraying, water filling for waterscape, as well as other industrial purposes.

二、 Major Water Treatment Technologies:

Main pollutants of bath wastewater are surfactants, organic compounds and dust. The processes, such as biochemical method, physic-chemical method, membrane bioreactor method and ultra-filtration, are all suitable for treating this wastewater, which can meet reuse standard. When wastewater volume is not so large, physic-chemical method will be more applicable due to its easy operation and stable running without affected by fluctuation of water quality; while the biochemical method is applied to the situations with relatively stable water quality and quantity, which is most widely used in Beijing; the water recovery rate of this method can reach over 90%. The membrane bioreactor (MBR) method can obtain the best effluent quality, but its investment is relatively higher; the ultra-filtration process can produce good effluent quality with low initial investment, however its following cost for membrane module replacement is relatively higher.

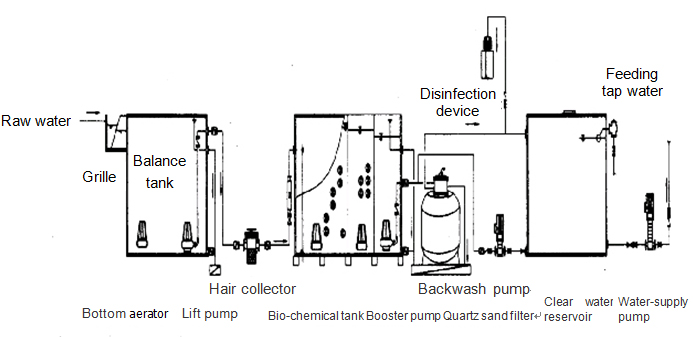

2.1 Biochemical Process Flow

2.2 Physic-chemical Process Flow

Source water →Balance tank → hair filter → flocculation sedimentation tank → sand filter → activated carbon adsorption →clear water reservoir

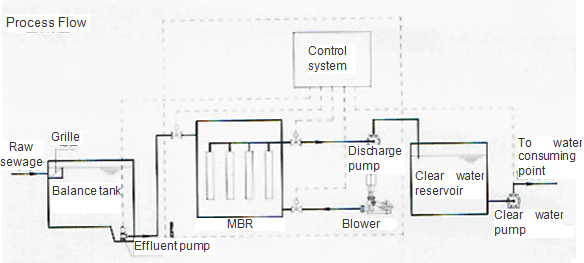

2.3 MBR Process Flow

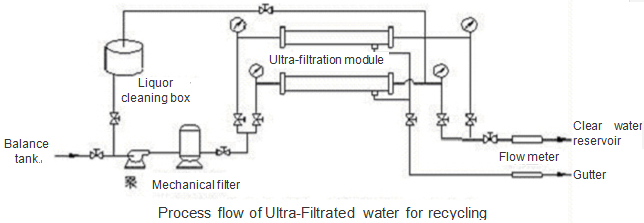

2.4 Ultra-Filtration Process Flow

Since 1997, Jianyan has undertaken over 100 reclaimed water projects, designed and installed four technologies above according to the actual situations and users’ demands, so it has gained rich experience, especially as an agent of Kubota liquid membrane products since 2001, Jianyan has obtained the domestic leading position in the field of MBR reactor.

Sewage Engineering

In the entities, such as community, villas and schools without municipal drainage pipe network, sewage must be treated and meet the relevant standard before discharge; such sewage is commonly treated by SBR method, biological contact oxidation method, CASS method, liquid membrane method and so on. Generally, the buried tank is appropriate for small water amount, which can employ the buried design with lawn planting for greening; or conduct in-depth treatment to meet the water reuse standard for recycling, such as toilet flushing, greening, road spray, water-supply for landscape, so as to achieve water reuse.

Membrane bioreactor (MBR) is a new technology to apply membrane technology in wastewater treatment. MBR can realize both microbial degradation of pollutants and pollutant separation by ultra-filtration membrane in a compact space, since synergy exist between degradation and separation, it is a kind of high efficient and practical wastewater treatment technology. Its effluent does not contain suspended matters, only small amount of disinfectant needs to be added so as to avoid secondary pollution of pipeline, it can be reused so as to make sewage recycling.

Industrial Wastewater Engineering

Based on our powerful technical strength and combined with domestic and foreign advanced water treatment technologies, Jianyan has made significant achievements of wastewater treatment in such industries as pharmaceutical, wine making, petrochemical, slaughtering, papermaking, printing and dyeing, food and electroplating.

Primary Technologies:

UASB Reactor

Anaerobic treatment is a complex biochemical process, which mainly relies on synergy of acidogenic bactria, hydrogen-producing acetogenic bacteria and methane-producing bacteria during hydrolysis, to decompose and convert organic matters in wastewater into substances, such as methane and carbon dioxide under conditions of anaerobic environment. The up-flow anaerobic sludge bed (UASB) reactor is a kind of suspension-growth digester without a carrier, which consists of reaction zone, precipitation zone and air chamber. Wastewater is flowed into the sludge bed from the bottom and mixed with sludge, so that microbes break down organic matter in wastewater to generate methane. With strong agitation caused by the rising bubbles, a suspended sludge layer can be formed at the upper sludge bed. A mixture of gas, water and sludge rises to a three-phase separator; when methane bubbles encounter a baffle plate at the bottom of the separator, they will bend to the gas chamber, and then effectively separated out; Sludge and water are flowed into the precipitation zone of three-phase separator through a channel, and separated under the effect of gravity; the supernatant is discharged from the upper precipitation zone, sludge at the bottom of the precipitation zone returns to the reaction zone along the skew wall.

SBR Process

The SBR (sequencing batch reactor) is to intermittently operate according to time sequencing. It can realize complete mixed in the space and complete plug flow in the time sequence, high reaction speed, and less volume of reaction tank required by SBR method for the same treatment efficiency in comparison with continuous processing tank. It is mainly featured as simple process flow, less structures, less land occupation, low construction and operation cost; good solid-liquid separation due to static precipitation, and high effluent quality; as well as flexible operation mode which can combine multiple process routes.

CASS Process

The CASS (cyclic activated sludge system) is a kind of circulating activated sludge process. Compared with SBR process, it increases a pre-reaction zone and its bioreactor is designed more optimally. In the CASS process, part of excess sludge in the main reaction zone returns to the selector, so it realizes continuous water feeding. CASS tank can withstand impact loads of water quality and quantity, and has a greater capacity to dilute industrial wastewater of high concentration; it canceled the primary and secondary precipitation tanks, so it is featured as simple process flow and convenient operation and management; less and simple machinery and equipment for not easy to malfunction and less maintenance, easy operation control and automatic control; less structures and compact layout of biological tank for less land occupation; good denitrification and dephosphorus effect; good stability of sludge; good dehydration performance; and less excess sludge generated, only about 60% of that generated in the traditional activated sludge process; therefore it is applicable to industrial wastewater treatment.

Aquaculture Wastewater Treatment Engineering

Aquaculture wastewater is a kind of high-concentration organic wastewater, which contains a large number of pathogens. If it is directly discharged into water body or flowed into water body with rain due to inappropriate storage, it may seriously deteriorate surface water or groundwater water. Due to very strong dissolubility of livestock and poultry manure, the components, such as nitrogen, phosphorus and organic matter in manure has large soluble capacity during raining, if it is not properly handled, it can pollute groundwater through surface runoff and infiltration. Its influences on surface water mainly reflect that, after a large number of organic matters enter into water body, the decomposition of organic matter will consume a lot of the dissolved oxygen in water, making water stink; When the dissolved oxygen in water is greatly dropped, some organic matters can continuously decompose and produce toxic gases under the anaerobic conditions, such as CH4 and HS, which can lead to massive death of aquatic life; Large amounts of suspended solids in waste water can make water turbid, reduce photosynthesis of algae in water, and limit normal activity of aquatic organisms, which make some organic pollution-sensitive aquatic life die gradually, thus further intensify oxygen shortage in the bottom of water body and reduce the assimilative capacity of water body; Nitrogen and phosphorus can cause eutrophication of water body, which result of over high concentration of nitrate and nitrite in water. The people and livestock may be poisoned in event of drinking this kind of water for long term. Some toxic algae may emit large amounts of toxins into water during their growth and mass propagation, leading to massive death of aquatic animals, which may seriously damage the water ecological balance; some epidemics can be spread when some bacteria, virus, etc in feces and urine flow with water.

The processes for dung liquid treatment in the large livestock and poultry farms can be classified into two main categories, namely comprehensive utilization and treatment for compliance discharge. Among them, the former is a good approach to utilize biomass energy in multilevel, build ecological agriculture and ensure the sustainable agricultural development.

Aquaculture Wastewater Treatment Process 1: solid-liquid separation

Whichever systems or comprehensive measures are employed to treat wastewater from livestock and poultry farm, the procedure of solid-liquid separation, as an essential step, must be firstly conducted, which importance and significance mainly lie in: Firstly, the farms generally discharge wastewater with suspended solids of high concentration, even up to 160,000 mg/L, correspondingly, the organic matter content is also high, the pollutant load in liquid will be greatly reduced through solid-liquid separation; Secondly, the solid-liquid separation can prevent the larger solids into subsequent procedures, and prevent equipment from damage or blockage, etc. In addition, solid-liquid separation can also increase reliability of the anaerobic digestion function, reduce sizes of the anaerobic reactor and necessary residence time, lower facility investment and improve COD removal efficiency before anaerobic digestion process. Generally, solid-liquid separation technology includes screening, centrifuge, filter, flotation, precipitation, sedimentation, and flocculation steps, etc. At present, there are some mature solid-liquid separation technologies and corresponding equipment; such equipment mainly includes screening centrifuge, horizontal centrifuge, filter press and hydro-cyclone, rotating conical sieve and centrifugal disc separator, etc.

Aquaculture Wastewater Treatment Process 2: anaerobic treatment

Since aquaculture wastewater contains high concentration of organic matters, N, P and harmful microbes, anaerobic process is an essential technology for waste treatment in livestock and poultry farm. For this kind of organic wastewater, the anaerobic digestion process can effectively remove large amounts of soluble organic matters with lower running cost; COD removal rate can reach 85~90%, and this procedure can kill infected germs, so it is helpful for farm epidemic prevention. If aquaculture wastewater treatment is directly utilized after solid-liquid separation of aerobic process, one-time investment can save 20%, but electricity consumption for flowing water is ten times more than that of anaerobic treatment due to large power consumption, so long-term operation cost will bring heavy economic burden to farms.

Aquaculture Wastewater Treatment Process 3: aerobic treatment

Aerobic treatment is to utilize aerobic microorganisms for wastewater treatment. Aerobic biological process can be classified into natural aerobic treatment and artificial aerobic treatment.

Natural aerobic biological treatment utilizes microbes in the natural water body and soil to purify wastewater, which is also called as natural biological treatment, mainly including water body purification and soil purification. The former mainly has oxidation pond (aerobic pond, facultative pond, anaerobic pond) and aquaculture pond, etc.; the later mainly has land treatment (slow percolation and rapid filter, ground sheet flood) and artificial wetland, etc. Natural biological treatment is featured as low capital cost and less power consumption; the removal rates of organic matter difficult to biodegrade, nitrogen and phosphorus nutrients and bacteria by this method are higher than those of conventional secondary treatment, even up to effect of tertiary treatment. In addition, comprehensive utilization of sewage by this method can be realized in combination with sewage irrigation under certain conditions. Its shortcomings mainly cover more land occupation and treatment effect vulnerable to seasonal fluctuation, etc. In event that farm is small and close to a waste pond and tidal flats available, this process shall be adopted to save investment and treatment costs as possible. Artificial aerobic biological treatment utilizes artificial intensive oxygen to improve aerobic microorganism vitality for wastewater treatment. The process mainly includes activated sludge method, bio-filter, biological rotating disc, biological contact oxidation method, SBR method, anaerobic/aerobic (A/O) and oxidation ditch method, etc. In terms of treatment effect, contact oxidation and biological rotating disc methods are better than the activated sludge process; the bio-filter also has good treatment effect, but it is easy to happen blockage in the filter. Oxidation ditch, SBR and A/O process can be classified as the modified activated sludge method. As oxidation ditch process is featured as good effluent quality and less sludge generated, it is also suitable for sewage denitrification, however its disadvantages include small BOD load, large land occupation and high operation cost. SBR process is featured as high automation degree, which can carry out deep treatment for sewage, but its shortages are small BOD load and large one-time investment. A/O process is a kind of activated sludge treatment doubled with BOD removal and denitrification, its investment is also relatively large, but wastewater is easy to meet the discharging standard after treatment by this process. Thus, A/O process is applicable for the large-sized breeding farm with more wastewater generated and strong economic capacity; while aerobic processes, such as contact oxidation and biological rotating disc methods, are suitable for the medium-sized farms.